Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

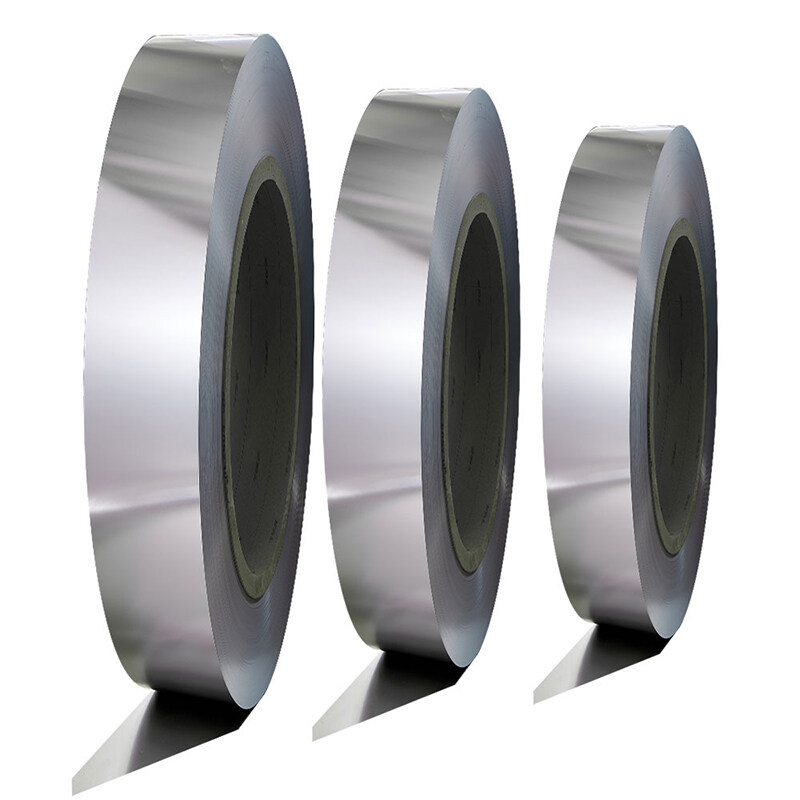

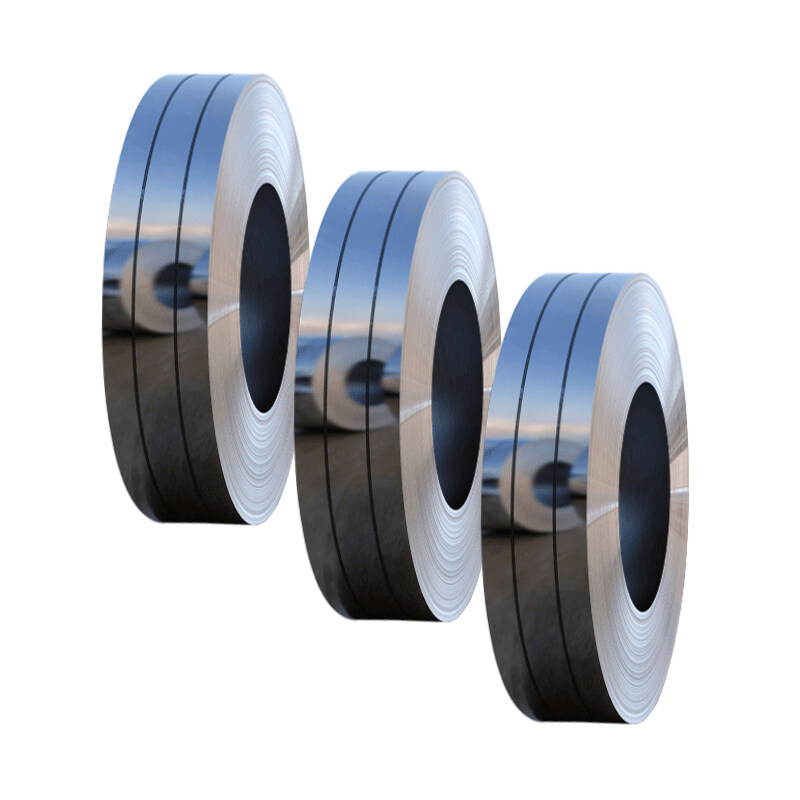

201 Hot cold rolling Stainless Steel Plate sheet coil strip belt

Our 201 stainless steel plate, sheet, coil, and strip are available in both hot and cold rolling production methods, with hot rolling being the mainstream option. This high-temperature tolerant material is highly resistant to corrosion and rust, ensuring its longevity for many years to come. By our advanced technology, it is in high quality and meet your any demand.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H,H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

Do you need Hot cold rolling Stainless Steel Plate sheet coil strip belt? This is our 201 301 304 304L 316 316L Hot cold rolling Stainless Steel Plate sheet coil strip belt, any interests, welcome to contact us!

Sqichen offers a wide range of stainless steel strip belts that are available in various widths, ranging from 0.3937″ to 47.2441″, with a thickness as thin as 0.0040″. The material used for these strip belts can be freely selected from 200 series to 300 series stainless steel, providing a wide range of options to choose from. With years of experience in the industry, Sqichen is capable of cutting strips with accurate measurements and advanced technology.

Fire-resistance:

The stainless steel is of the highest quality, ensuring that it can withstand high temperatures to a certain degree. This makes it an ideal material for use as a fireproof wall, providing excellent fireproof functionality without compromising its color or shape. Its exceptional heat resistance ensures that it remains structurally sound and retains its original appearance, even in the most extreme conditions.

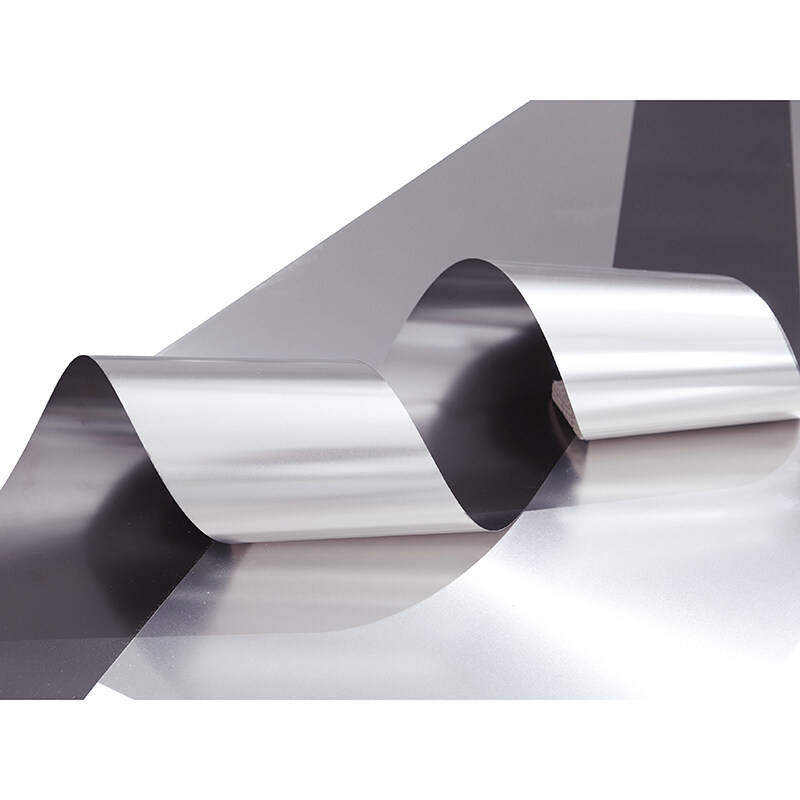

Exceptional Surface Smoothness:

We offer a variety of surface treatments for our stainless steel products, including 2B, BA, N0.1, NO.4, and more. Each treatment provides a different level of surface smoothness, allowing to choose the best option for their specific needs. Our 8K surface treatment, in particular, produces a bright mirror-like finish that is even smoother than 2B and BA treatments. This is because it is processed from these treatments, resulting in a surface that is exceptionally smooth and reflective.

Professional:

As a professional factory with years of experience in researching stainless steel, we take pride in offering products that meet international standards. Our commitment to high quality and exceptional service ensures that our clients receive the best possible experience, with convenience and sincere enthusiasm at the forefront of everything we do. Our dedication to excellence is reflected in every aspect of our business, from our research and development to our customer service.

Product Parameter:

|

Material |

Stainless Steel |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

2B / BA /NO.1/ NO.4/HL/8K/6K |

|

Grade |

Stainless Steel |

|

Standard |

ASTM |

|

Surface Finish |

No.1 |

|

Length |

10-12000mm or Customized |

|

Thickness |

0.1mm or Customized |

|

Certification |

RoHS, JIS, ISO9001 |

|

Width |

10mm-1200mm or As Request |

|

Tolerance |

±1% |

|

Processing Service |

Cutting, Bending, Decoiling |

|

Application |

Electrical Appliances, Medical Instruments |

Application:

- Construction: for building facades, roofing, and cladding;

- Automotive: such as exhaust systems, mufflers, and heat shields;

- Aerospace: such as aircraft frames, engine components, and landing gear;

- Food and Beverage: such as tanks, pipes, and fittings;

- Medical: such as surgical instruments, implants, and medical devices.

Hot rolling and cold rolling are the forming processes of section steel or steel plate, which have a great impact on the microstructure and properties of steel. The rolling of steel is mainly hot rolling, and cold rolling is only used to produce small section steel and sheet.

Hot-rolling

Advantage

It can destroy the casting structure of ingot, refine the grain of steel, and eliminate the defects of microstructure, so that the steel structure is dense and the mechanical properties are improved. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; Bubbles, cracks and porosity formed during pouring can also be welded under high temperature and pressure.

Disadvantage

1.After hot rolling, the non-metallic inclusions (mainly sulfides, oxides, and silicates) in the steel are pressed into thin sheets, resulting in delamination (interlayer). Delamination greatly deteriorates the tensile properties of steel along the thickness direction, and it is possible to have interlaminar tearing when the weld shrinks. The local strain induced by weld shrinkage often reaches several times of the yield point strain, which is much larger than the strain caused by load;

2.Residual stress caused by uneven cooling. Residual stress is the stress of internal self-equilibrium without external force. Hot rolled sections of various sections have this kind of residual stress. Generally, the larger the section size of the section steel is, the greater the residual stress is. Although the residual stress is self balanced, it still has a certain impact on the performance of steel members under external forces. For example, it may have adverse effects on deformation, stability, fatigue resistance, etc.

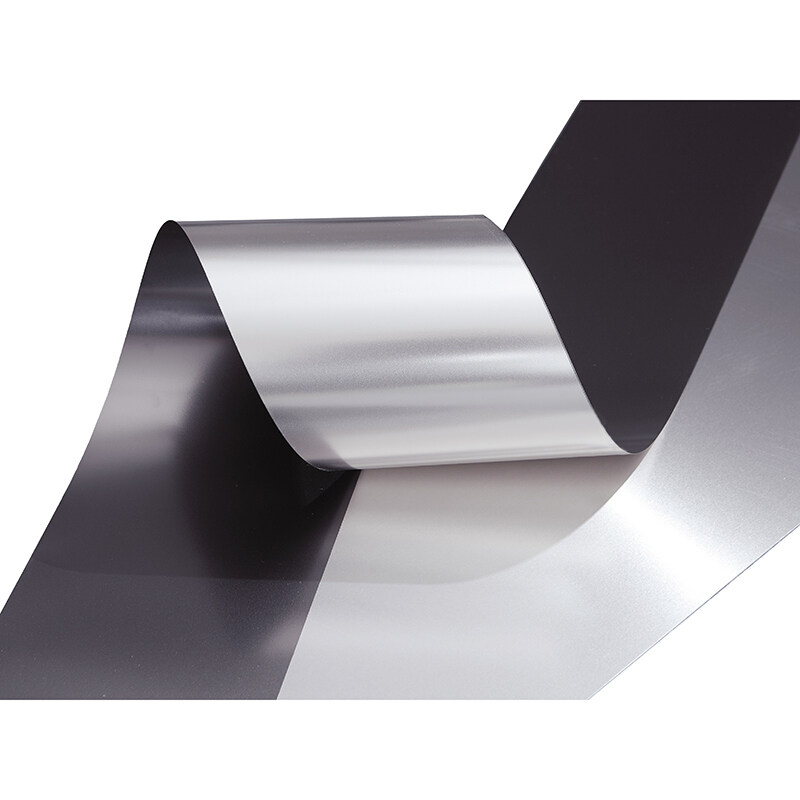

Cold rolling

It refers to the processing of steel plates or strips into various types of steel at room temperature through cold drawing, cold bending, cold drawing and other cold processing.

Advantage

It has fast forming speed, high output, and does not damage the coating. It can be made into a variety of cross-section forms to meet the needs of service conditions; Cold rolling can produce great plastic deformation of steel, thus improving the yield point of steel.

Disadvantage

1.Although there is no hot plastic compression in the forming process, there is still residual stress in the section, which will inevitably affect the overall and local buckling characteristics of steel;

2.The style of cold rolled section steel is generally open section, which makes the free torsional stiffness of the section low. Torsion is easy to occur in bending, bending and torsional buckling is easy to occur in compression, and the torsional resistance is poor;

3.The wall thickness of cold rolled formed steel is small, and there is no thickening at the corner of the plate connection, so the ability to bear local concentrated load is weak.

What we have

Floor space: more than 20,000 square meteres

Production capacity: annual production capacity of more than 10,000 tons

16 years experience: Focus on the precision metal alloy material industry for more than 16 years.

Our services

- Customers' Request

- Free Sample

- Special Surface Processing

- Second Treatment according to customer requirements, such as: surface, width, etc.

Logistics

Transportation: sea, land

Delivery time: 15-25 working days

Packing: plastic film inside, woven bag outsourced and transported in a custom wooden box.

FAQ

Q: What is the MOQ?

A: MOQ: 500kg.

Q: What is your delivery time?

A: 7-25 working days.

Q: What is the payment method?

A: 30% deposit is paid in advance before production, and the balance is paid before shipment

Q: Can you guarantee the quality of the product?

A: Yes, we can.

Q: Are you a factory or a trading company?

A: Industry and trade integration

Q: Where is your factory?

A: Room 101, Building B, No. 3 Education North Road, Yixin Community, Pingdi Street, Longgang District, Shenzhen, welcome to visit.

Q: Are custom services available?

A: Yes, they are available.

Q: Do you support OEM and ODM?

A: Yes.

Q: Why choose us?

A: We have a number of slitting, shearing, electroplating, painting, wire drawing surface treatment production lines, which can meet the needs of different customers, rich market resources, sufficient inventory, complete specifications, and a complete technical team.

Q: Does your packaging ensure product safety?

A: Yes, we adopt quality package.

Q: What information do I need to provide to get an accurate quote?

A: Please provide us with these information: material, hardness, surface, width, thickness.

Q: How can I get product progress without going to your company?

A: We provide one-to-one customer service.

Q: How can I deal with this if I don't receive the item?

A: We will have special personnel responsible for following up the logistics of the goods.

Q: How is your after-sales service?

A: The company will have special personnel responsible for following up the logistics of the goods.

Q: Can samples be ordered?

A: Yes, they can.

Q: How much is the sample fee, can it be refunded after bulk product?

A: Samples are free, so all no fees are refunded.

Q: Do you provide quality assurance?

A: Yes.

Q: Do you support providing samples?

A: Free sample (without shipping).

Q: What is the monthly supply capacity?

A: 1000 tons/month.